Produce with innovation and sustainability

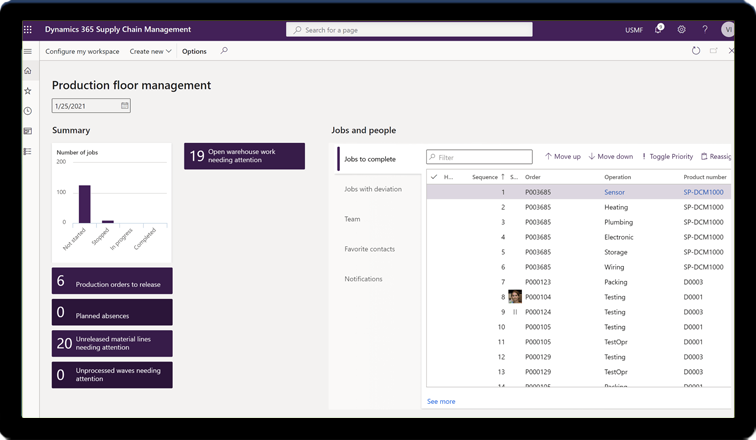

Create a connected factory; Proactively manage the shop floor using a real-time view of production and stock to improve quality, increase throughput, and reduce downtime with modern production floor execution user interfaces.

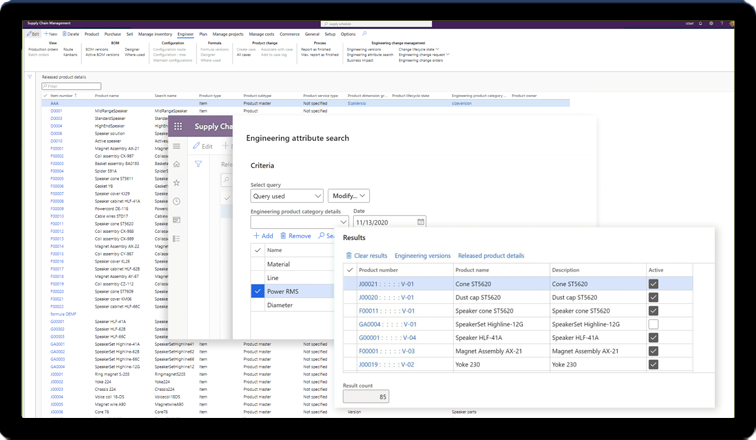

Innovate with intelligent manufacturing; Implement sustainable and adaptable manufacturing processes using the Internet of Things (IoT) and mixed reality to accelerate time to market for new products.

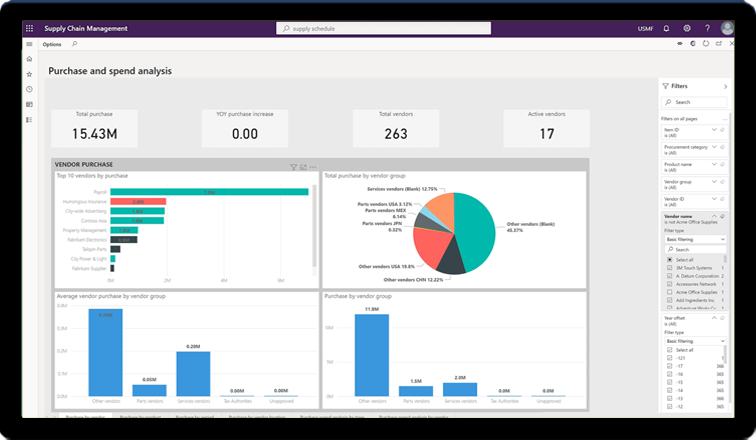

Enhance visibility of the production floor; Incorporate data from external manufacturing execution systems to eliminate data silos, improve quality, and optimize production processes with manufacturing execution systems integration.

Keep production running continuously; Easily scale production during peaks and keep critical manufacturing processes running in remote locations, even when disconnected from the cloud, by using scale units at the edge.

Transform your workforce; Improve safety, increase efficiency, and reduce errors by using the interactive holographic experience in Dynamics 365 Guides.